Essential Tools for Furniture Designers: Care and Maintenance

Chisels

Chisels are indispensable for shaping wood and adding intricate details to furniture. They demand regular sharpening to maintain their edge, as a dull chisel can slip and ruin your work or even cause injury. Cleaning chisels after each use by wiping down the blade and handle helps prevent rust and buildup from adhesives or finishes. It’s essential to store chisels in a dry environment, ideally in cases or with protective caps, to avoid accidental nicks or exposure to moisture. Additionally, periodically inspecting the handle for cracks ensures safe handling and effective force application during use.

Hand Saws

Hand saws are fundamental for accurate cutting, and maintaining their sharpness is crucial for clean results. Regularly check the teeth of the saw for dullness or damage, and use a saw file to restore their edge as needed. Residue, like sawdust or pitch, can build up on the blade, so cleaning with a cloth and mild solvent keeps the cut smooth and reduces friction. Lubricating the blade occasionally minimizes rust and improves performance. Store hand saws hanging on designated racks to prevent bending or accidental damage and ensure safety in a busy workshop.

Planes

Planes are used to smooth and shape wood surfaces with precision. Their blades must be kept razor-sharp; otherwise, they tear the grain rather than slicing it cleanly. Dismantle the plane occasionally to clean internal mechanisms of dust and resin, which can impede movement. Adjusting and tuning the body and knobs ensures consistent performance. Apply a light coat of oil to any exposed metal parts to protect against corrosion, and always store planes upright or on their side to prevent blade dullness and accidental damage to the cutting edge.

Power Tools

Routers

Routers are highly versatile for creating edges, joints, and detailed designs in wood. To maintain peak performance, keep router bits sharp and free from resin buildup, which can cause overheating and degrade cuts. Clean the collet regularly so that bits can be inserted and locked securely. Dust and debris can accumulate in the motor housing, so periodic vacuuming or blowing out with compressed air is recommended. Lubricating moving parts according to the manufacturer’s instructions prevents premature wear and ensures consistent results.

Table Saws

Table saws are essential for making straight, precise cuts. Keeping the blade sharp prevents burning the wood and reduces the risk of kickback. Dust is a significant issue; install dust collection systems and clean the saw’s internals regularly. Alignment of the fence and miter gauge should be checked frequently to maintain accuracy. Lubricate moving parts such as the arbor, gears, and elevation mechanisms to keep adjustments smooth. Always unplug before performing maintenance and inspect safety features like blade guards and anti-kickback pawls for optimal protection.

Sanders

Sanders ensure smooth surfaces and are crucial for the finishing process. Regularly replacing worn-out sandpaper keeps sanding efficient and prevents unnecessary strain on the tool. Dust buildup can clog motors and affect performance, so clean the sander thoroughly after each use, paying special attention to vents and moving parts. Inspect power cords and switches for signs of wear, as damaged components can pose serious safety risks. Store sanders in a dry area to prevent rusting, especially on exposed metal surfaces, and avoid stacking heavy items on top of them.

Previous slide

Next slide

Sharpening stones, whether water, oil, or diamond-based, require their own maintenance to remain effective. Clean stones after each use to remove metal filings and slurry, which can clog the surface and reduce sharpening efficiency. Flatten the surface regularly with a lapping plate or leveling stone to prevent uneven wear. Store in a dry environment, and if using water stones, soak them before use but allow complete drying afterward to avoid cracking or mold growth.

Honing guides help maintain consistent blade angles during sharpening. Over time, debris and oil can accumulate in the moving parts, affecting the guide’s precision. Disassemble and clean the guide periodically, ensuring rollers spin freely and adjustment knobs operate smoothly. Inspect for signs of wear or loose parts, tightening or replacing components as needed. Store honing guides in a clean, dry location away from heavy objects that might cause them to lose calibration or get bent.

Strops bring the final razor edge to blades. They typically require the application of honing compound, which can accumulate and lead to buildup over time. Clean strop surfaces occasionally by scraping off excess compound and conditioning the leather if required. Store strops flat to prevent curling or misshaping, and avoid exposure to humidity, which can degrade both the leather and any glued joints. Regularly inspect the strop for nicks or uneven spots, addressing them promptly to ensure a uniform honing surface.

Workshop Environment

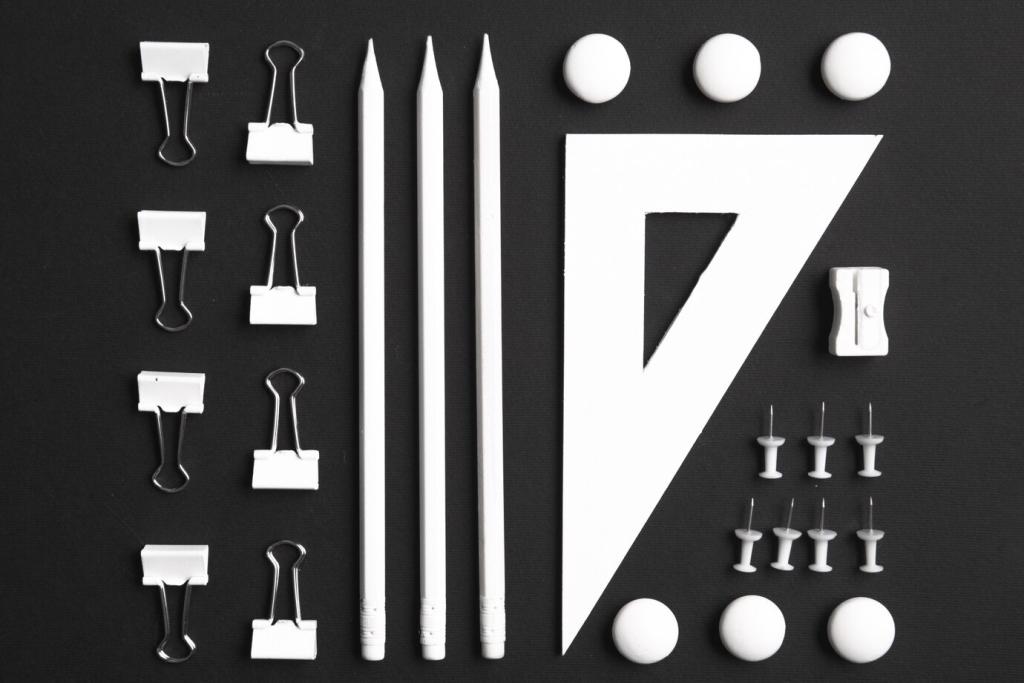

A well-organized workspace ensures that tools are easy to find and safely stored. Design custom storage solutions such as wall-mounted racks, drawers, and shelving tailored to specific tools. Ensure that each tool has its designated spot, reducing the risk of damage caused by dropping, stacking, or over-crowding. Regularly re-evaluate your setup for efficiency and make adjustments as your tool collection grows or your workflow changes. Streamlined organization improves productivity and protects your investment in quality tools.

Eye Protection

Eye injuries can have lasting consequences, so high-quality safety glasses or face shields are a non-negotiable in the workshop. Clean lenses frequently with a soft cloth and approved cleaner to maintain clear visibility. Inspect frames for cracks and ensure the fit is snug but comfortable, adjusting as needed. Replace any damaged or heavily scratched safety gear immediately, and store in a protective case to avoid contamination or accidental breakage.

Hearing Protection

Prolonged exposure to the loud sounds of power tools can cause permanent hearing loss. Earmuffs or earplugs must be kept clean and free from dust for optimal efficacy. Wash or replace tips and pads on a regular schedule, following manufacturer guidelines. Store hearing protection in a dust-free, cool area to ensure longevity. Check for signs of wear or loss of cushioning and replace components as soon as they show signs of degradation.

Respirators and Dust Masks

Fine dust and airborne particles are a significant hazard in woodworking shops. Invest in high-quality respirators and dust masks, and ensure a proper fit each time they are worn. Filters should be replaced according to the manufacturer’s instructions, or whenever breathing resistance increases. Store these items in sealed containers or dust-free areas to prevent contamination. Regular cleaning of reusable masks with appropriate solutions is necessary to maintain hygiene and effectiveness.

Storage Solutions

Tool cabinets offer secure, dust-free environments for storing both hand and power tools. Invest in sturdy, lockable cabinets with foam-lined drawers to cushion delicate items. Label drawers or use transparent fronts for easy access and inventory management. Clean interiors regularly to prevent dust and moisture accumulation, checking for signs of rust or pests that could affect your collection. By keeping your most used items within arm’s reach, you save time and reduce the risk of accidental damage from cluttered benches.